Sheet metal forming JSTAMP

-

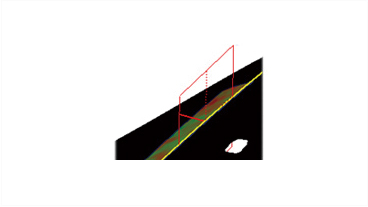

Crack

-

Wrinkle

-

Springback

-

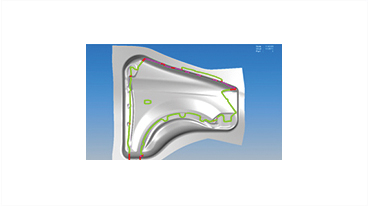

Expected die

-

Die structure examination

- Products

- JSTAMP

Sheet metal forming JSTAMP

Request a Consultation

-

Crack

-

Wrinkle

-

Springback

-

Expected die

-

Die structure examination