Do you face any of these challenges?

- Looking to apply simulation technologies to the research and development of healthcare materials but unsure how to proceed

- Wanting to adopt data-driven approaches in healthcare materials R&D but hindered by a lack of skills or data

- Seeking to accelerate collaborative development with peers or cross-industry partners by leveraging DX-based technologies

Comprehensive Software Solutions and Expert Support for Driving DX in Healthcare Materials Development

JSOL offers a comprehensive portfolio of simulation and AI technologies essential for advancing digital transformation (DX) in healthcare-related materials R&D, covering the wide range of functions and techniques required in areas such as biocompatible materials, sensing materials, medical device coatings, drug delivery materials, and tissue engineering scaffolds. Applications include simulating molecular interactions at biological interfaces, predicting mechanical and chemical stability in physiological environments, modeling fluid dynamics in medical devices, optimizing sensor material performance, and leveraging AI for property prediction and design optimization.

Software package is designed for ease of use, and our expert support services—built on extensive experience—help even first-time users quickly integrate these tools into their work and research.

JSOL’s solutions are trusted by manufacturers, research institutions, and healthcare innovators worldwide. By leveraging our network and platform, we provide opportunities for user-to-user communication and collaboration directly through JSOL’s software. When required, JSOL can also coordinate and support the creation of research frameworks that bring together companies, universities, and other partners—empowering joint innovation in healthcare materials development.

Integrated Solution for Multiscale Simulation and Data Science

- Proven Track Record in Industry and Academia

- Software for Multiscale Simulation

- Software for Materials Informatics

In healthcare-related research and development, it is essential to optimize the properties of a wide range of materials, such as biocompatible materials for regenerative medicine and sensing materials for wearable devices. These materials span diverse categories—including carbon-based materials, inorganic nanomaterials, conductive polymers, and biomaterials—each requiring a thorough understanding of their unique characteristics.

By using J-OCTA, it is possible to perform simulations tailored to each scale, ranging from nanometer-scale phenomena such as electronic states and molecular structures to micrometer-scale features such as phase-separated morphologies, as well as to integrate simulations across these scales.

In recent years, there has been a growing demand for data-driven R&D utilizing AI technologies, driven by concepts such as AI-driven drug discovery and materials informatics. With J-OCTA’s AI capabilities, users can predict physical properties—taking into account factors such as molecular composition, blend ratios, and processing conditions—or perform inverse analysis to identify optimal formulations and processes. In cases where data scarcity is a challenge, large-scale simulations can be used to generate synthetic datasets. Likewise, simulations can be combined with machine learning to validate model predictions by analyzing the underlying mechanisms.

01Proven Track Record in Industry and Academia

02Software for Multiscale Simulation

In healthcare-related research and development, it is essential to understand the diverse material properties required for applications such as biocompatible materials for regenerative medicine and sensing materials for wearable devices. Other important areas include bioresorbable polymers, inorganic nanomaterials for diagnostics, conductive polymers for biosensors, hydrogels for tissue engineering, and materials for implantable medical devices.

Because no single simulation method can cover the full range of length scales and phenomena involved, JSOL offers integrated solutions that combine multiple techniques. J-OCTA is specifically designed to support multiscale analysis, enabling simulations from nanometer-scale phenomena—such as molecular structures and interactions—to micrometer-scale features like phase-separated morphologies and composite structures.

J-OCTA covers the simulation capabilities needed for comprehensive multiscale property analysis in healthcare applications, as well as in related fields such as drug discovery, pharmaceutical formulation, and biomedical device engineering. Since the amount of experimentation required at the design stage can be enormous, J-OCTA also facilitates the use of simulation to efficiently accumulate data for materials informatics or AI-driven R&D. For more details, please visit the dedicated websites for each software package.

03Software for Materials Informatics

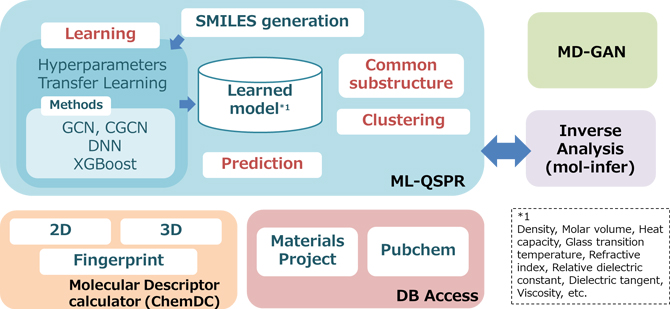

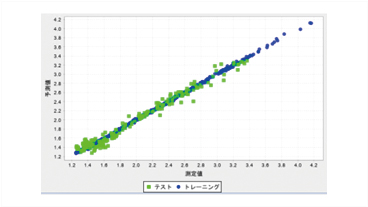

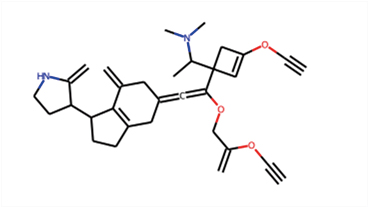

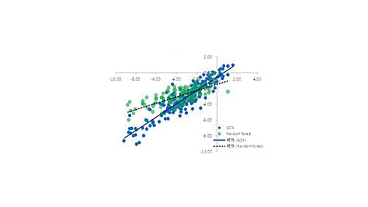

J-OCTA MI-Suite includes machine learning capabilities for predicting material properties using molecular/crystal structures and various conditions as explanatory variables, along with related features such as molecular descriptor calculations, access to public databases, and analysis of each variable’s contribution.

When experimental data are insufficient, the software can supplement them with simulation results. It also provides API functionality to support database construction using physical simulations.

Data selection and learning condition settings for machine learning can be performed via dialogs, without the need for programming. Multiple pre-trained models are included, allowing users to start Materials Informatics projects even without their own data.