Properties of Cross-Linked Phenolic Resins [Courtesy of Sumitomo Bakelite Co., Ltd.]

Full-Atomistic Molecular Dynamics (FAMD) was used to evaluate the relationship between crosslinked structure and properties of phenolic resin. Structures were created by crosslinking linear oligomers, and three types with crosslinking degrees of 70%, 82%, and 92% were examined. Higher crosslinking degree increased glass transition temperature, and a clear dependency on crosslinking degree was observed in stress–strain behavior.

Use Cases Highlights

- Evaluation of the relationship between crosslinked structure and properties of thermosetting phenolic resin

- Modeling of complex three-dimensional structures

- Relationship between reaction rate and material properties

Evaluation of the relationship between crosslinked structure and properties of thermosetting phenolic resin

A crosslinking reaction model of phenolic resin is shown. Three structures with crosslinking degrees of 70%, 82%, and 92% are created using linear oligomers (nonamers) and evaluated by Full-Atomistic Molecular Dynamics (FAMD).

Cross-linking reaction model of phenolic resins

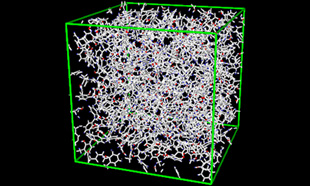

Modeling of complex three-dimensional structures

Simulation results of the crosslinking reaction of phenolic resin are shown. The effects of different crosslinking degrees on structural formation can be visually confirmed.

Simulation of crosslinking reaction

Relationship between reaction rate and properties

The specific volume change for each crosslink density is shown, indicating a trend of increasing glass transition temperature (Tg) with increasing crosslink density. This suggests that molecular motion is suppressed by crosslinking.

Change in specific volume: red, D = 70%; blue, D = 82%; green, D = 92%

Reference

[1] A. Izumi, T. Nakao and M. Shibayama, Soft Matter, 2012, 8, 5283-5292.

Inquiries Regarding Products

Have questions about product implementation? Contact us today.