Do you face any of these challenges?

- Looking to apply simulation or AI technologies to the development of electronic materials and components

- Wanting to leverage your in-house data for data-driven design and optimization

- Seeking access to the latest DX-driven technologies for advanced electronics manufacturing and materials development

Comprehensive Software Suite and Robust Support to Realize Materials DX

In the electronics industry—encompassing semiconductors, batteries, high-speed communication technologies such as 5G/6G, and advanced displays—there is a growing demand for research and development of materials that enable next-generation devices.

JSOL offers a broad portfolio of simulation and AI technologies essential for the development of such advanced electronic materials. Each software package is designed for ease of use, and our expert support services—built on extensive experience—help even first-time users quickly integrate these tools into their work and research.

Our J-OCTA is built on OCTA, an open-source platform developed through a national industry–academia collaboration project in Japan. Today, it is widely used by manufacturing companies and research institutions worldwide. By leveraging the open-source community, we create opportunities for user-to-user communication and collaboration directly through JSOL’s software.

When required, JSOL can also coordinate and support the creation of research frameworks that bring together companies, universities, and other partners—empowering joint innovation in materials development for the electronics sector.

Integrated Solution for Multiscale Simulation and Data Science

- 01. Proven Track Record in Industry and Academia

- 02. Software for Multiscale Simulation

- 03. Software for Materials Informatics

In the electronics industry, there is a growing demand for research and development of materials used in a wide range of devices, including semiconductors, batteries, high-speed communication technologies such as 5G/6G, and displays. At the same time, evaluating the properties of these materials requires an understanding of their multiscale characteristics and the application of a variety of methods and technologies.

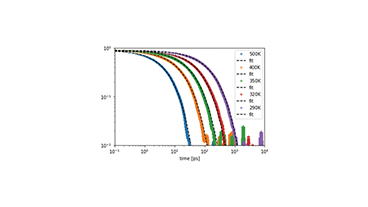

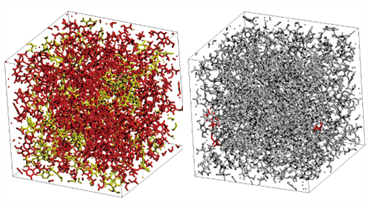

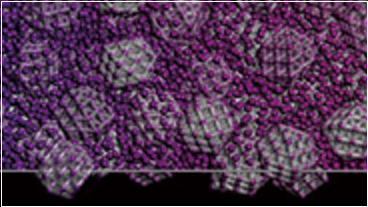

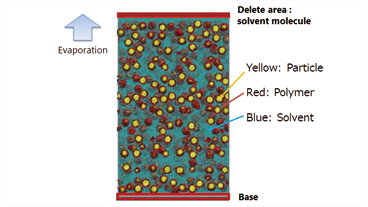

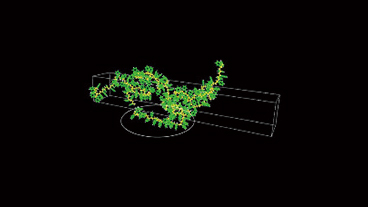

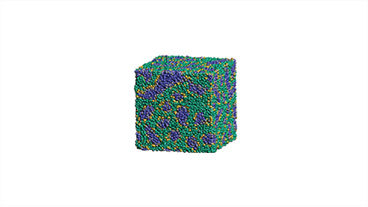

With JSOL’s simulation software suite, you can run simulations tailored to each scale: from nanometers, capturing electronic states and molecular structures, to micrometers, modeling phase separation and composite materials. By linking these tools, it is possible to analyze the mechanisms behind the performance of advanced materials directly through simulation.

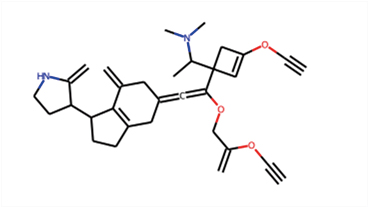

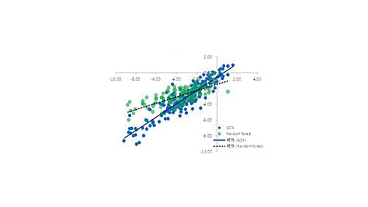

Today, there is growing demand for data-driven materials development using AI technologies, under concepts such as Materials Informatics and Process Informatics. JSOL’s AI-enabled software allows you to predict properties based on molecular and crystal structures, composition ratios, and processing environments—and even perform inverse design. When experimental data is scarce, high-throughput simulations can be executed to supplement datasets and accelerate discovery.

01Proven Track Record in Industry and Academia

02Software for Multiscale Simulation

In materials design, it is essential to determine which scale—from nanometers to micrometers—has the greatest impact on material properties.

No single simulation method can cover all scales and phenomena. That’s why we offer multiscale-ready software, combining multiple engines (solvers) into a single materials design solution.

This enables comprehensive simulation capabilities to analyze the multiscale characteristics of a wide range of materials.

Learn more on each product’s dedicated page.

03Software for Materials Informatics

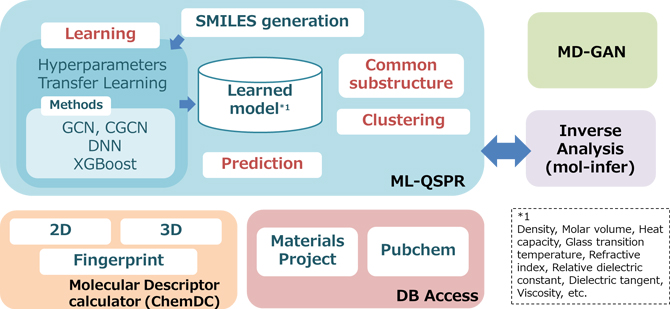

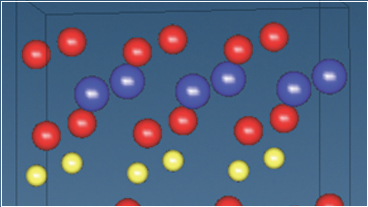

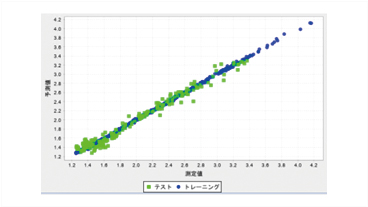

J-OCTA MI-Suite includes machine learning capabilities for predicting material properties using molecular/crystal structures and various conditions as explanatory variables, along with related features such as molecular descriptor calculations, access to public databases, and analysis of each variable’s contribution.

When experimental data are insufficient, the software can supplement them with simulation results. It also provides API functionality to support database construction using physical simulations.

Data selection and learning condition settings for machine learning can be performed via dialogs, without the need for programming. Multiple pre-trained models are included, allowing users to start Materials Informatics projects even without their own data.