Slurry Coating Process [Courtesy of Toyota Motor Corporation]

To improve the performance of fuel cells and lithium-ion batteries, the slurry coating process during electrode fabrication was analyzed. Coarse-Grained Molecular Dynamics (CGMD) using VSOP was employed to reproduce porous structures after solvent evaporation, and finite difference calculations using Muffin were performed to evaluate diffusivity and conductivity. The series of analyses demonstrated that optimizing porous structures by controlling polymer adsorption performance is important for enhancing battery performance.

Use Cases Highlights

- Analysis of slurry coating processes for battery electrodes using VSOP

- Porous structures accompanying solvent evaporation

- Simulation of properties based on created structures

Analysis of phenomena during battery electrode slurry coating using VSOP

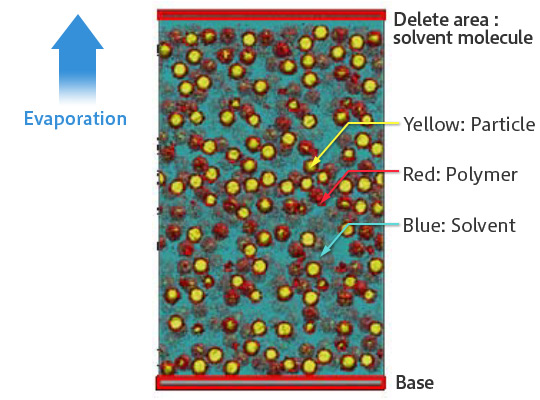

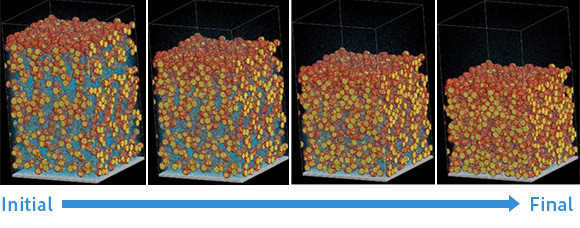

Results of simulating the solvent evaporation process in slurry using VSOP are shown. Particle and polymer arrangements change with evaporation, affecting final structure formation.

Analysis of solvent evaporation process (VSOP)

Porous structure accompanying solvent evaporation

The porous structure formed after evaporation is shown. The distribution of particles, polymers, and voids can be visually confirmed, providing useful information for the structural design of battery electrodes.

[Results] Solvent evaporation process (VSOP)

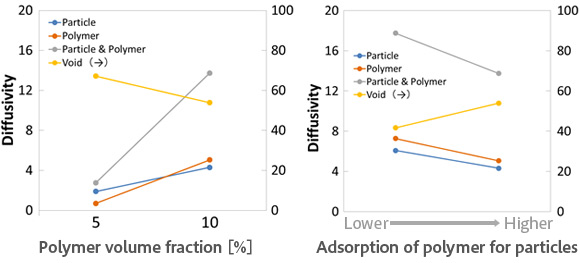

Simulation of properties based on generated structures

Results of evaluating the diffusivity and conductivity of porous structures using Muffin are shown. The effects of differences in polymer volume fraction and adsorption performance are compared.

[Results] Diffusion/conduction performance of porous structures (Muffin) — (left) effect of polymer volume fraction, (right) effect of adsorption performance

Reference

[1] HPCI Research Report Vol.3 (2018) 89-94

http://www.hpci-office.jp/annex/resrep/?p=1143

http://www.hpci-office.jp/annex/resrep/?p=1143

Details of analysis

Inquiries Regarding Products

Have questions about product implementation? Contact us today.