Simulation of evaporation of liquid film

- Filler density distribution analysis during evaporation and drying using the particle method

- Capability to handle fillers of different particle sizes

- Analysis of the effect of drying processes on particle segregation

Analysis of filler density distribution during evaporation and drying using the particle method

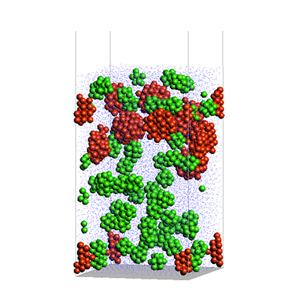

An evaporation–drying model of a liquid film containing two sizes of fillers is shown. Using the Moving Particle Simulation (MPS) method, the model reproduces how fillers aggregate at the film surface as the solvent decreases during evaporation. This allows visual observation of particle behavior during drying.

Capability to handle fillers with different particle sizes

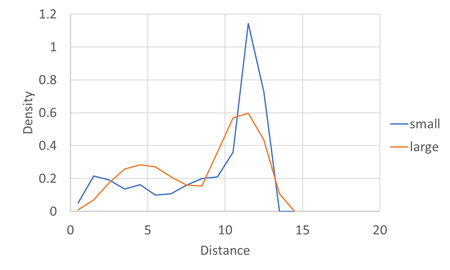

The density distribution of fillers in the thickness direction of the membrane at the final stage of evaporation drying is shown. Smaller fillers are distributed with higher density near the membrane surface compared to larger fillers, clearly indicating a tendency for particle segregation. This enables prediction of particle arrangement in the membrane structure after drying.

Analysis of the effect of drying process on particle segregation

The particle structure after evaporation and drying is visualized as an isosurface. The three-dimensional representation shows particle distribution and aggregation states, providing useful information for evaluating the effects of drying conditions and particle properties on the final structure.