Calculation of pressure and porosity in the forming process (calendaring) of battery electrodes

The discrete element method (DEM), a type of particle method, was used to analyze the pressure distribution and porosity changes during the calendering process of battery electrodes. The influence of forming conditions on electrode structure was quantitatively evaluated, contributing to process design for optimizing battery performance.

Use Cases Highlights

- Compression–extension simulation of solid (powder) layers using the particle method (DEM)

- Capability to analyze porosity

Compression/extension simulation of solid (powder) layers using the particle method (DEM)

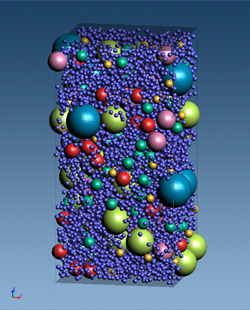

An initial particle structure created using the RVE modeler in J-OCTA is shown. Active material and binder are randomly placed with different particle sizes, mimicking the structure of actual electrode materials.

Initial particle structure calculated with the RVE modeler of J-OCTA

Analysis of porosity

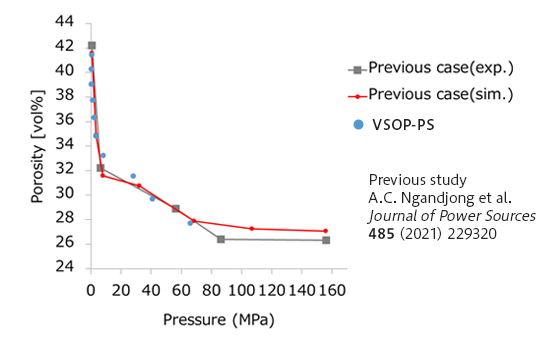

A graph showing the relationship between pressure on the upper wall and porosity during elongation is presented. The calculation results by VSOP-PS (blue circles) show good agreement with experimental and computational results from previous studies, confirming the validity of the model.

Relationship between pressure applied to the upper wall and porosity during the elongation process

Inquiries Regarding Products

Have questions about product implementation? Contact us today.