Simulation of Crosslinked Epoxy Resin

Using J-OCTA’s reaction modeler, Molecular Dynamics simulations were performed for the crosslinking reaction between bisphenol-A epoxy resin and ethylenediamine curing agent. Evaluation of glass transition temperature (Tg) for models with varying crosslink densities showed a trend of Tg increasing with higher crosslink density, demonstrating the usefulness of simulations for material design.

Use Cases Highlights

- Evaluation of the relationship between crosslinked structure and properties of thermosetting epoxy resin

- Modeling of complex three-dimensional structures

- Evaluation of properties of thermosetting resins

Evaluation of the relationship between crosslinked structure and properties of thermosetting epoxy resin

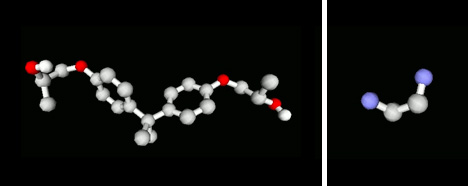

Construction of molecular models of bisphenol-A epoxy resin and ethylenediamine curing agent using J-OCTA is shown. The epoxy is on the left and the curing agent on the right, in the preparation stage for the reaction modeler.

Modeling of molecules using J-OCTA (left: EP, right: ethylenediamine)

Modeling of complex three-dimensional structures

The crosslinking reaction simulation of epoxy resin using J-OCTA’s reaction modeler is shown. Structural changes with reaction progress can be visually confirmed.

Simulation of crosslinking reaction

Evaluation of properties of thermosetting resins

The temperature dependence of specific volume under a crosslink density condition of 29% is shown. Tg is evaluated from the inflection point of the temperature–specific volume curve.

Specific volume at each temperature (29%)

Details of analysis

Inquiries Regarding Products

Have questions about product implementation? Contact us today.