Rheology Simulation of Rubber [Courtesy of Sumitomo Rubber Industries, Ltd.]

To evaluate dynamic viscoelastic properties (tanδ) related to tire rolling resistance, simulations were performed for crosslinked polyisoprene rubber using the primitive chain network (PCN) model in NAPLES. The effect of the distribution of molecular chain crosslinking positions on tanδ was analyzed, showing that terminal crosslinking is effective in reducing rolling resistance.

Use Cases Highlights

- Analysis of the relationship between tire rolling resistance and rubber molecular crosslink structure

- Simulations useful for material design

Analysis of the relationship between rolling resistance of tires and crosslinked structure of rubber molecules

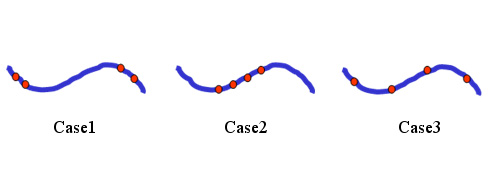

The distribution of crosslinking positions in the molecular structure of crosslinked polyisoprene rubber is shown. NAPLES is used to evaluate the effect of crosslinking on a polymer with molecular weight of 300,000.

Distribution of cross-link on polymer chain

Simulations useful for material design

The frequency dependence of tanδ for different crosslink structures (case1–case3) is shown. In terminally crosslinked structures, tanδ is lower in the low-frequency region, suggesting a contribution to reducing rolling resistance.

Calculated tanδ in each case

Inquiries Regarding Products

Have questions about product implementation? Contact us today.