Material properties of phase-separated structures of block copolymer-nanoparticle composites

Dissipative Particle Dynamics (DPD) was used to calculate phase-separated structures formed by three types of diblock copolymers with different block ratios composed of polymer A and polymer B. The obtained phase-separated structures were transferred to Digimat-FE for deformation and thermal conductivity analysis using nonlinear Finite Element Method (FEM). Furthermore, the structure when nanofillers with high affinity for one component were added was predicted, and property evaluation was also performed.

Use Cases Highlights

- Evaluation of phase-separated structures in diblock copolymers

- Evaluation of physical properties using Finite Element Method

- Utilization for dispersion of nanofillers during phase separation

Phase-separated structures of diblock copolymers

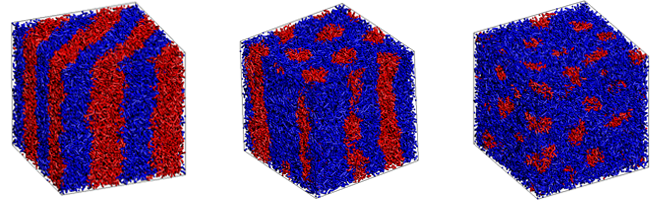

DPD simulation of phase-separated structures of three polymers with different block ratios (A10B10, A6B14, A3B17) is shown.

Results of phase-separated structures obtained by DPD (left: A10B10, center: A6B14, right: A3B17)

Physical property evaluation using Finite Element Method

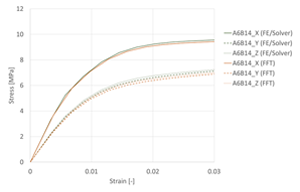

The obtained phase-separated structure was transferred to Digimat-FE in STL format, and deformation and thermal conductivity analyses were performed using nonlinear Finite Element Method. The figure shows deformation analysis results for a cylindrical phase-separated structure formed by an A6B14 diblock copolymer, with anisotropy observed in the stress–strain curves.

Tensile analysis results by Finite Element Method

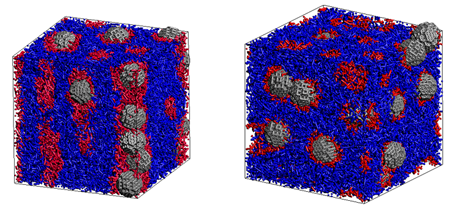

Dispersion of nanofillers during phase separation

The structure when nanofillers with high affinity for component A were mixed was predicted, and property evaluation was performed. Details are included in the linked video.

Dispersion structure of nanofillers

Inquiries Regarding Products

Have questions about product implementation? Contact us today.