Cyclic Deformation of Filled Rubber [Courtesy of The Yokohama Rubber Co., Ltd.]

To evaluate the relationship between dispersion structures and mechanical properties of filler-reinforced rubber used in tires, Coarse-Grained Molecular Dynamics (CGMD) simulations using VSOP were performed. Dispersion structures were compared with agglomerated structures, and stress responses and hysteresis phenomena under repeated elongation were analyzed. It was shown that the polymer state between fillers influences stress softening, providing insights for material design.

Use Cases Highlights

- Relationship between dispersion structure and mechanical properties in filler-filled rubber

- Detailed analysis of stress–strain curves

- Analysis of the origin of hysteresis

Relationship between dispersion structures and mechanical properties of filler-reinforced rubber

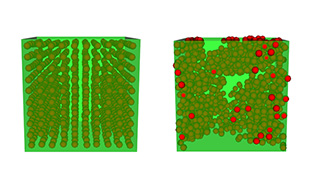

A model of silica-filled rubber with dispersed and aggregated structures constructed using VSOP Coarse-Grained Molecular Dynamics (CGMD) with the Kremer–Grest model is shown. The subsequent mechanical response under repeated elongation/unloading is analyzed.

Calculation model (left: dispersed, right: aggregated)

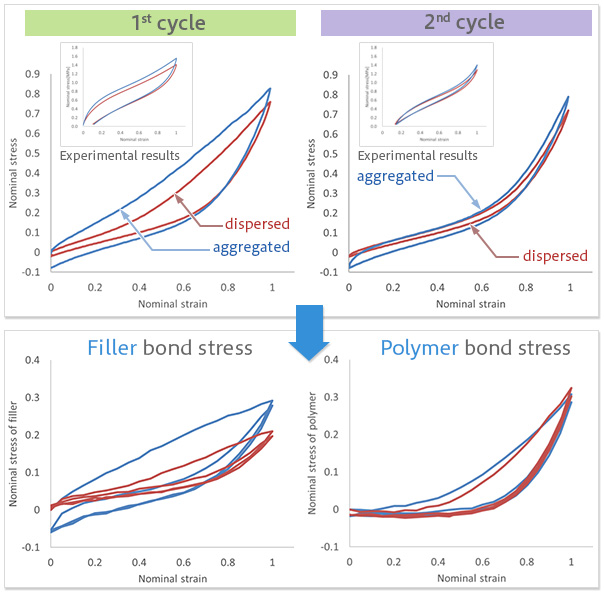

Detailed analysis of stress–strain curves

Stress–strain curves for the first and second cycles are shown, indicating that filler distribution influences macroscopic mechanical response.

[Results] Stress–strain curves

Analysis of the origin of hysteresis

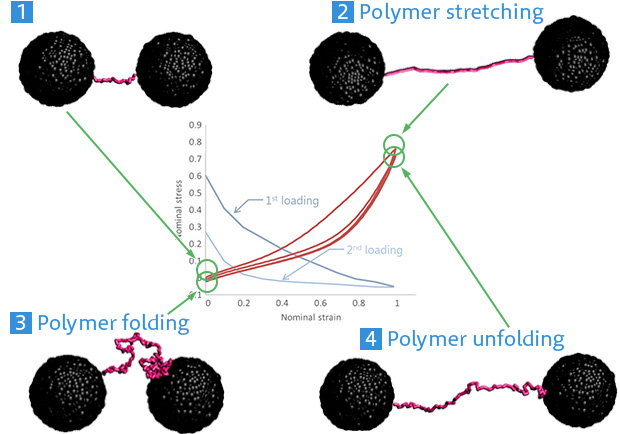

Polymer chains between fillers during tensile and unloading are shown. During the first elongation, polymers bridging between fillers are pulled out, causing stress softening in the second elongation after unloading, as visually confirmed.

Polymer chains between fillers (representative examples extracted)

Details of analysis

Inquiries Regarding Products

Have questions about product implementation? Contact us today.