Viscosity of the suspension

The particle method (MPS) was used to evaluate the viscosity of filler dispersion systems in suspensions. The effects of filler concentration and dispersion state on viscosity were analyzed, contributing to slurry design and coating process optimization. By considering particle–particle interactions in the fluid, viscosity behavior consistent with experiments was reproduced.

Use Cases Highlights

- Viscosity evaluation of filler dispersion systems in fluids using the particle method (MPS)

- Capability to analyze the effect of filler volume fraction

Evaluation of viscosity in filler dispersion systems using fluid analysis with the particle method (MPS)

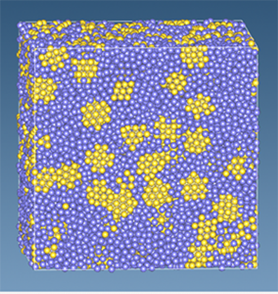

A computational model of a suspension using VSOP-PS is shown. The left side is a micro-model representing solid fine particles as multiple bonded particles, and the right side is a meso-model representing them as single particles. The micro-model can reproduce detailed particle shapes, while the meso-model is suitable for systems with many particles.

Calculation of suspensions using VSOP-PS (micro model)

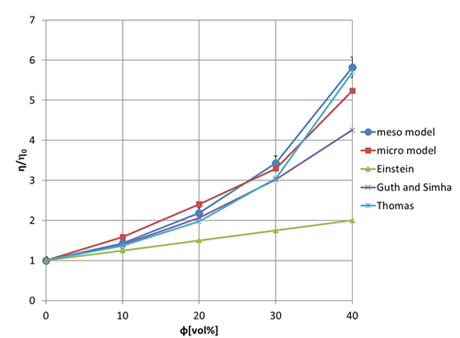

Capability to analyze the effect of filler volume fraction

A graph showing the relationship between the volume fraction of solid particles and the viscosity of suspensions is presented. Results from micro- and meso-models using the particle method (VSOP-PS) show good agreement with the Thomas model, especially in the high-concentration region, confirming the validity of viscosity evaluation using particle methods.

Relationship between suspension viscosity and volume fraction of solid particles

Details of analysis

Inquiries Regarding Products

Have questions about product implementation? Contact us today.