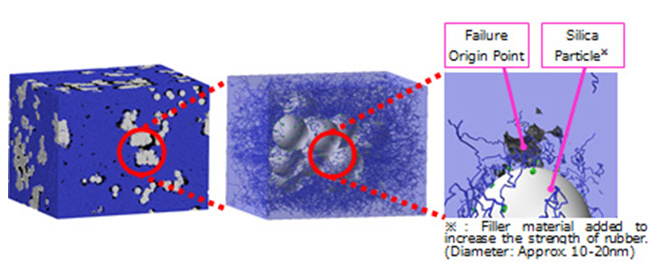

Enhanced wear resistance of tire [Courtesy of Sumitomo Rubber Industries, Ltd.]

Large-scale Coarse-Grained Molecular Dynamics (CGMD) simulations were performed on a supercomputer to analyze the fracture process of rubber materials. The results were applied to understanding tire wear mechanisms and designing actual materials.

Use Cases Highlights

- Fracture process of rubber materials via Coarse-Grained MD on a supercomputer

- Proven track record in actual product development

- Evaluation of interfacial debonding phenomena

Fracture process of rubber materials analyzed by Coarse-Grained MD on a supercomputer

The dispersion structure (350 nm on a side) of silica aggregates in rubber material, created to reproduce actual materials, and the deformed state obtained from Coarse-Grained Molecular Dynamics (CGMD) are shown. Interfacial debonding and void formation in the rubber are observed, visualizing structures that become fracture initiation points.

Peeling around silica aggregates and void formation in rubber

Proven track record in actual product development

A photograph of a wear-resistant concept tire developed based on this analysis is shown. By reflecting the analysis results in the design, the work contributed to actual product development, leading to the achievement of the Tire Technology Awards 2017.

Concept tire actually developed, winner of the Tire Technology Awards 2017

Reference

[1] https://www.srigroup.co.jp/english/newsrelease/2015/2015_130.html

[2] (in Japanese) https://www.jstage.jst.go.jp/article/gomu/89/6/89_176/_pdf/-char/ja

[2] (in Japanese) https://www.jstage.jst.go.jp/article/gomu/89/6/89_176/_pdf/-char/ja

Details of analysis

Inquiries Regarding Products

Have questions about product implementation? Contact us today.